“The solutions Maple Leaf Photonics provide meet our needs at a price we cannot get anywhere else.”

Dr. Alvaro Casas Bedoya, The University of Sydney

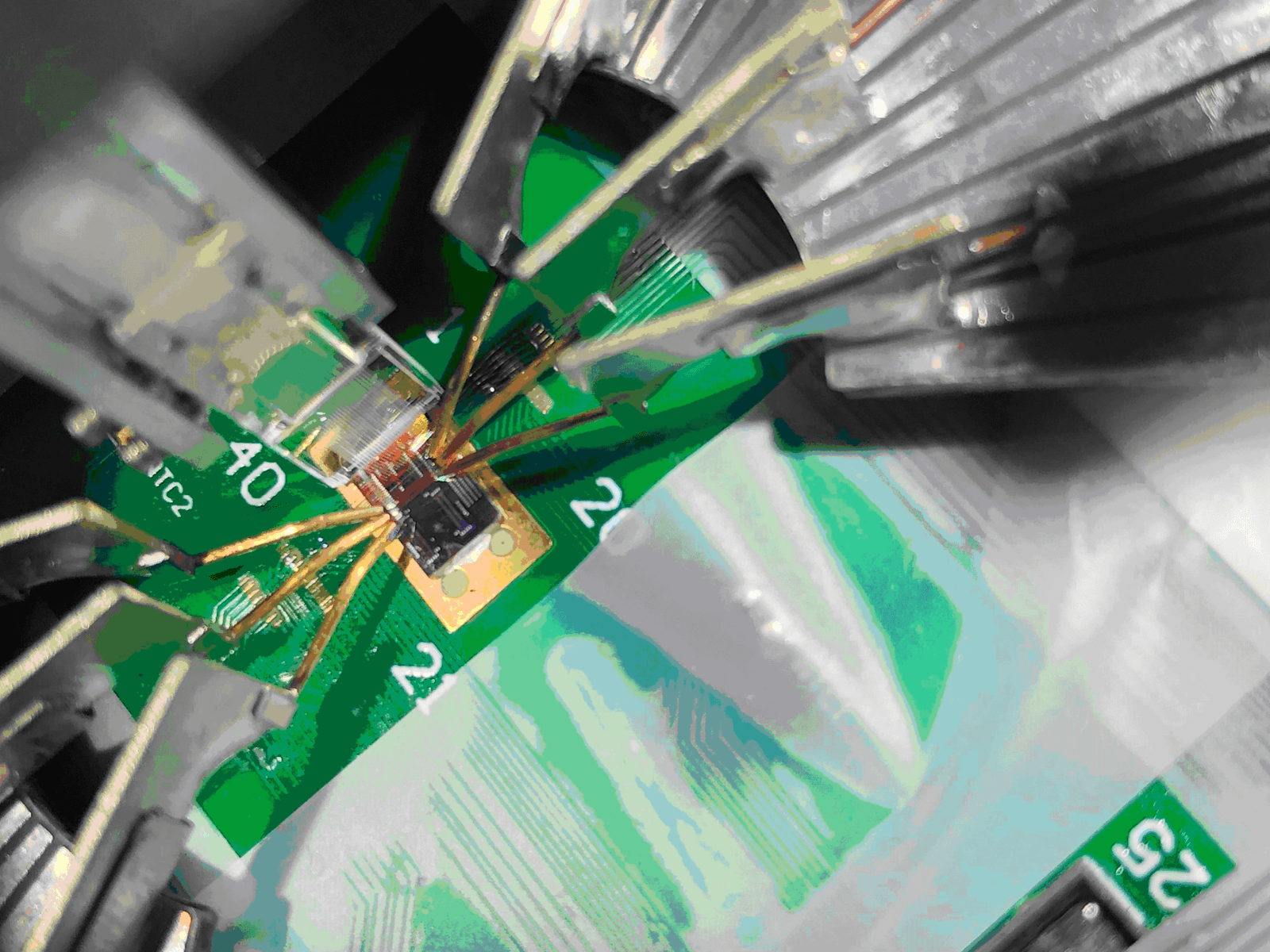

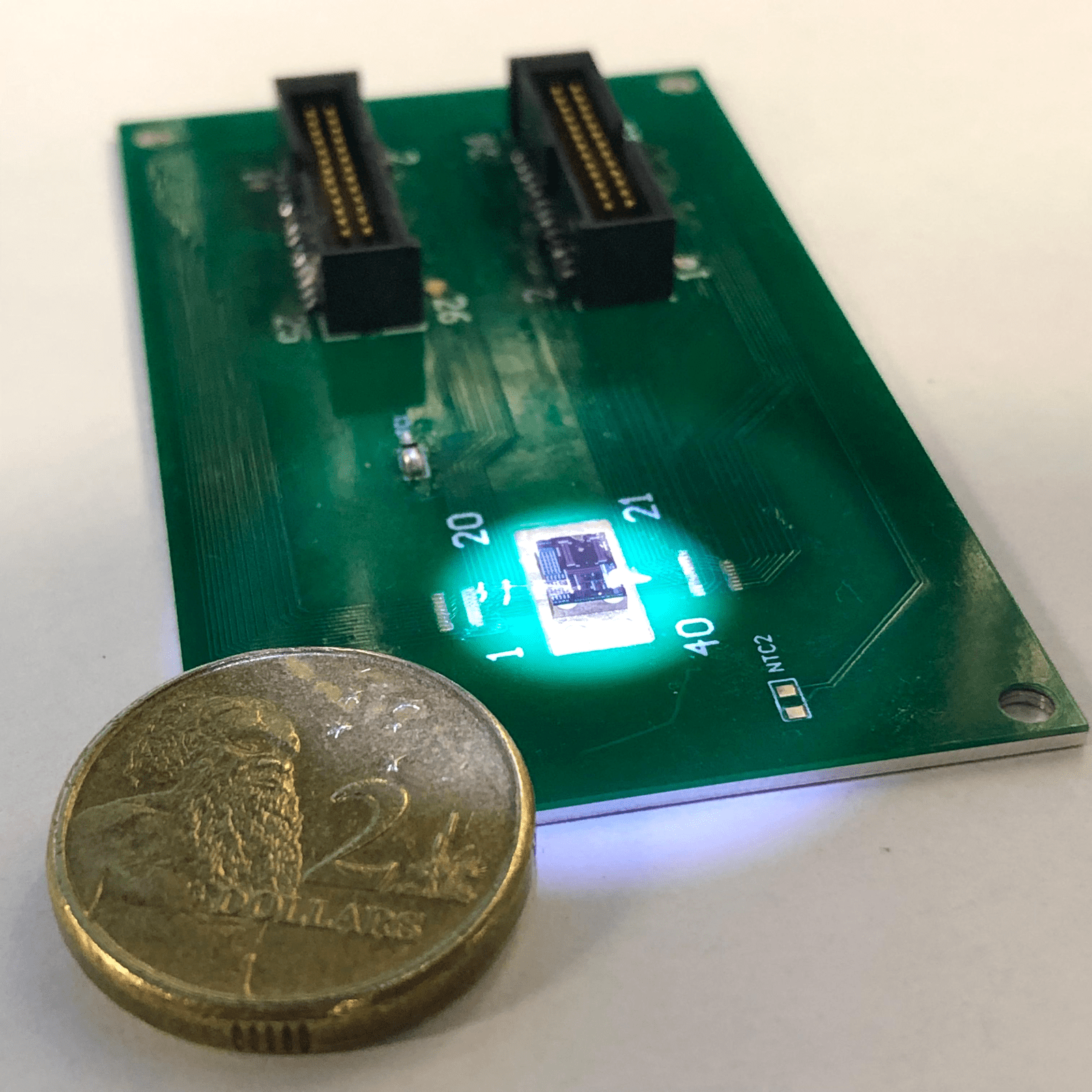

Dr. Alvaro Casas Bedoya leads photonic nano-fabrication and novel research projects in the Eggleton Research Group at The University of Sydney, Australia. The group pushes the limits of ultrafast, ultrabroadband signal processing for RF photonic applications. Dr. Casas Bedoya's most recent achievements involve the demonstration of nonlinear phase shifters based on Brillouin-scattered waveguides. Such novel RF phase shifters are particularly important for beam steering in phased array antennas in many applications such as satellite communications, RADAR, medical imaging, 5G networks, and sensing.

Challenges in Photonic Testing: Affordability and Capacity

Prior to acquiring a Maple Leaf Photonics probe station, Dr. Casas Bedoya and his researchers relied on manual stages to test their devices. Landing electrical probes and aligning fibers by hand bottlenecked the advancement of their research and mission. They needed an affordable probe station capable of automating fiber alignment and testing hundreds of devices in a single test run. Many of the commercial systems available were too costly or did not have the capabilities they needed for testing.

Solution: Customized Probe Station, On-site Training, and Follow-on Support

Dr. Casas Bedoya discussed his testing requirements with us at Maple Leaf Photonics. Because of our extensive background in testing photonic integrated circuits, we understood his needs and customized a probe station specific to his circuits and testing requirements.

“Maple Leaf Photonics was great to work with and took the time to understand our needs. And they not only came onsite to assemble and train us but also were available afterwards for support.”

Our probe station drastically improved efficiency for Dr. Casas Bedoya and his researchers. The automated scanning and aligning of fibers to on-chip devices greatly improved the team’s productivity, repeatability, and the reliability of their characterization data. As the complexity of their devices continues to increase, Maple Leaf Photonics customized their system to focus on packaging and gluing large-channel count arrays directly to their chips.