“Maple Leaf Photonics offers a great value for what you are getting. It meets our needs and is an easy system to use.”

Dr. Stefan Preble, Professor in the Kate Gleason College of Engineering at RIT

Dr. Stefan Preble pushes the limits of integrated photonics research and trains tomorrow's photonics researchers and engineers at the Rochester Institute of Technology. His focus on high performance computing and communications include quantum and nonlinear optical circuits that require state-of-art fabrication processes, packaging technologies, and characterization equipment. In addition to research, his mission with integrated photonics education and workforce development seeks to train the next generation of photonic technicians, scientists, and engineers. Using the Maple Leaf Photonics probe station, he teaches students how to design, fabricate, and test their own silicon photonic designs.

PiC Testing Needs: Repeatability and Reliability of Data

Dr. Preble’s research in quantum integrated photonics often requires multi-channel electrical controls and biasing that work in concert with optical test equipment. Prior to acquiring a Maple Leaf Photonics probe station, characterizing integrated photonic circuits required the manual alignment of probes and fibers, significantly impacting repeatability and reliability of the acquired data. The test and measurement process proved to be a costly bottleneck in advancing his research. Dr. Preble explored many commercially available probe stations and decided to purchase a customized probe station from Maple Leaf Photonics.

Solution: Adaptable Electro-optic Testing and Integrated Multi-channel Source Measurement

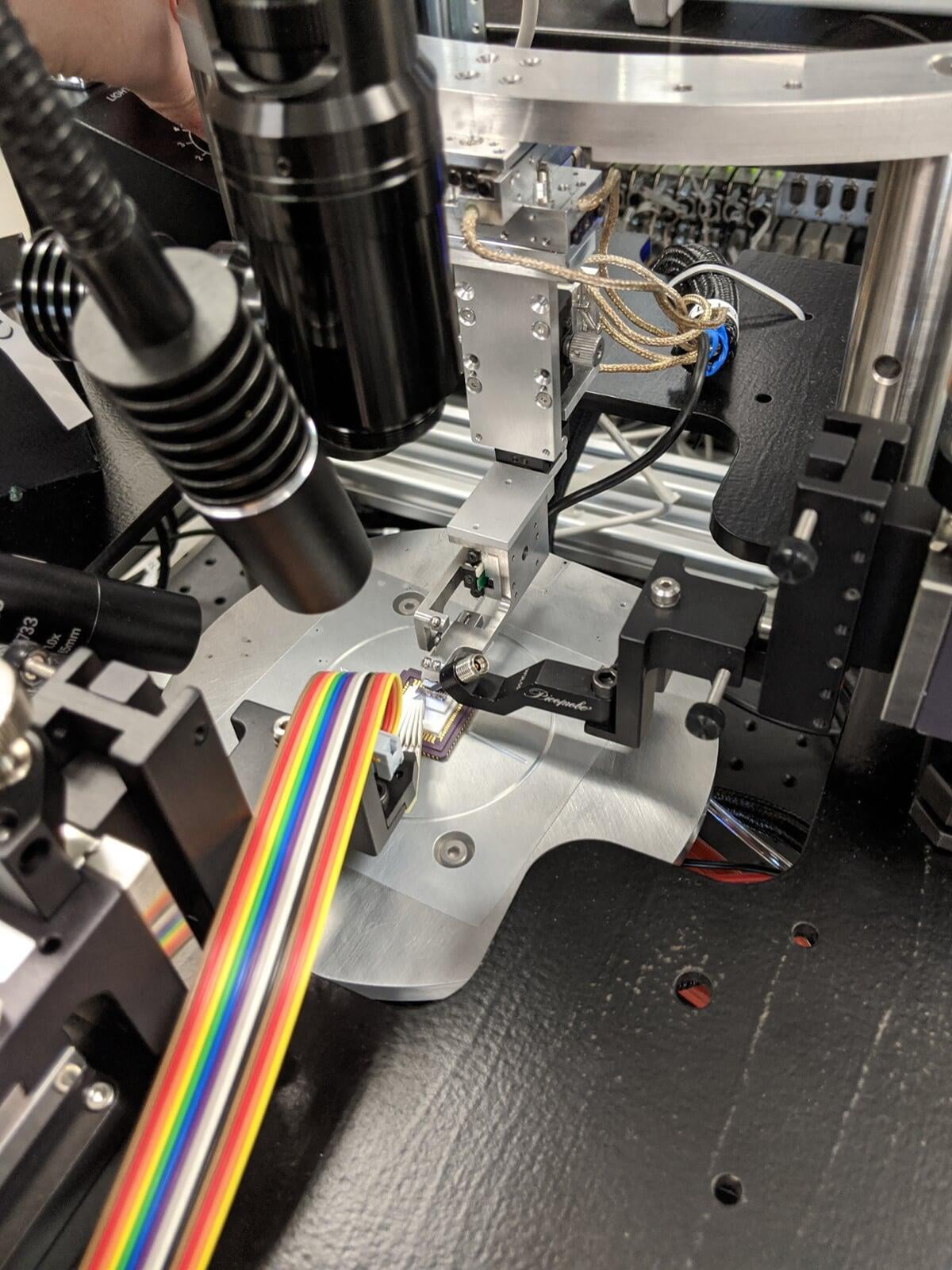

Dr. Preble uses a customized version of the Maple Leaf Photonics wafer probe system to test electro-optics on both wafers and single die. MLP’s integrated, multi-channel source measurement unit helps his team manipulate and characterize quantum entangled light. The MLP system was built to handle up to a six-inch wafer.

“The ability to easily switch from edge to vertical coupling as well as the ability to work with existing bench-top instruments were significant bonuses for us when choosing a system.”

MLP Probe Station Facilitates International Engineering Competition

In collaboration with AIM Photonics, Dr. Preble teaches an EdX course to students and engineers from around the world. There is “a huge demand for this course content,” Dr. Preble notes, and teaches students how to design & tapeout an electro-optic PiC that can be submitted directly to the AIM Photonics 300mm wafer foundry.

Dr. Preble expects hundreds of people will travel to RIT to participate in workshops that include hands-on characterization of PIC circuits using the Maple Leaf Photonics system. Dr. Preble looks forward to leveraging MLP’s latest software capabilities, such as its API and Python interface, to further customize the probe system and test environment. He foresees multiple probe stations in his lab, each optimized for different needs, such as automated fiber-chip-fiber applications.